Artist Interview – Carl

Fisher

Glass Addiction

JAC1961

July 11, 2007

Welcome to another artist interview at Glass

Addiction. This interview is provided to us by Carl & Fran Fisher. I've included

some follow-up questions at the end so I can still feel like I did something!

Hope you enjoy reading it and welcome Carl and Fran to our Glass Addiction

marble family!

~~~~~~~~~~~~~~~~~~~~

Both vintage and contemporary marble collectors worldwide collect Carl Fisher

handmade contemporary clay marbles. Although he only started making marbles in

2006, Fisher has been featured in over 15 local and national newspaper and

magazine articles. He is fast becoming one of the most highly collected

contemporary marble artists of our time.

We interviewed Carl Fisher on July 11, 2007 and here’s what he had to say:

Q. Tell me a little bit about yourself.

A. I was born in Cleveland, but grew up in Youngstown,

Q. What motivated you to start making marbles?

A. I collected marbles for years. As my vintage collection grew, I began getting

interested in the rarest, most colorful, and unfortunately, the most expensive

marbles. An antique, hard to find, multi-color shooter in mint condition could

easily cost hundreds, if not thousands, of dollars. I went to a local antique

show in February, 2006 looking for marbles and instead, I found a woman selling

some beaded necklaces that looked like some of the rarest old colorful marbles.

I asked her where she got them and she told me that she made them from polymer

clay. So, the next day, I drove out to the local craft store to pick up a few

packs of the brightly colored clay and hurried home to make my first marble. I

can remember grabbing a few small pieces of the red, yellow and blue clay and

kneading them together, and after just a few short minutes, there it was, a big

lump of clay that looked absolutely nothing like a marble, let alone the vintage

Superman I was trying to mimic. But, I kept at it for weeks. After a while, I

figured out how to get the clay rounder. Then I figured out how to get them to

look glossy like glass. Then I started to be able to more closely copy the

colors and patterns of the marbles that I sought for my own collection. Every

now and then, one would come out really nice, which at that time was still

mostly due to trial and error or just dumb luck. But, into my collection it went

as a placeholder until I could find or afford a real glass one. I showed some of

my placeholders to my marble collecting friends and they were amazed at how they

looked. They asked me to make some placeholders for their collections, too. So I

did, and that was the beginning of my marble-making career.

Q. Do you make any other marbles besides the vintage looking ones?

Yes, I also make my own contemporary designs. There is large group of people who

collect new works from contemporary marble artists. I create marbles for both

groups of collectors. It was at the

Q. How are your marbles different than regular glass marbles?

A. The biggest difference is the weight. Once you hold one of mine, you can

immediately tell its not glass. Its lighter, softer, and warmer to the touch

than glass. Mine are more durable though. They wont crack, break, or chip. You

can even bounce them off of a carpeted floor with no damage at all.

Q. Your marbles are like little works of art. What kind of paint do you use?

A. Everyone asks that. Actually, there is no paint used in the process. Polymer

clay is available in many different colors. I further hand blend these colors

together and then artistically form the clay to create the designs and patterns

on the marble. It takes a lot of trial and error to get the clay to look like

glass.

Q. Are there any other skills involved?

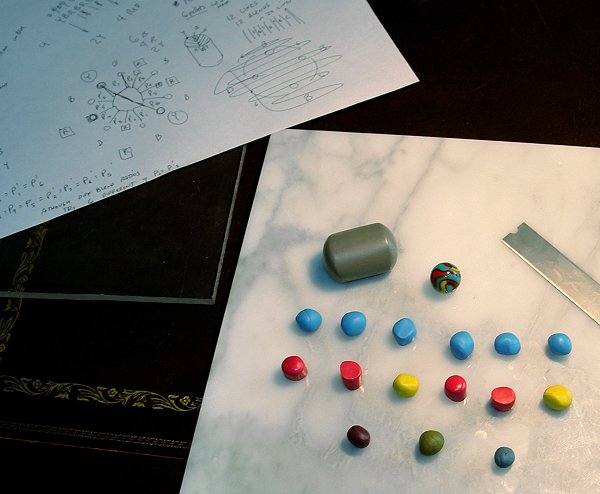

A. Beside artistic skills, theres a lot of math and science involved in the

process, especially if you want to be able to produce a consistent, high

quality, repeatable product. My engineering background helped out a lot with all

the measuring, weighing, and other technical stuff needed to make the marbles. I

designed and built a few simple machines to help in the manufacturing process to

get uniformly consistent sizes, colors, and patterns. Plus, I document

everything I do. So, if I need to reproduce a certain marble, I can review my

notes and create the marble. For example, if Im making a set of marbles, I know

that volume of clay in each marble has to be the same. The weight has to be the

same, too. I can simply weigh out equal amounts of clay for each marble to

ensure that they all come out the same size.

Q. How did you learn how to make these marbles?

A. I learned mostly by trial and error. There were no books on the subject. I

did look at some of the polymer clay How To books on making things from polymer

clay. I also studied some basic glass making techniques and tried to apply them

to clay. But most of what I use was learned by just doing it. There were a lot

of mistakes along the way and lots of bad marbles during the process. And, I

have jars full of uninteresting globs of clay to prove it.

Q. What have you been working on lately?

A. I’m working on some new patterns and designs and coming out with sets of

marbles like the Fisher Flower Series and the Food series. One of my best

customers recently purchased my Broccoli Quiche design and said that it looked

delicious. Its never ending. Some nights, I have to get out of bed and write

down some ideas just so I wont forget them. Every time I see something new, I

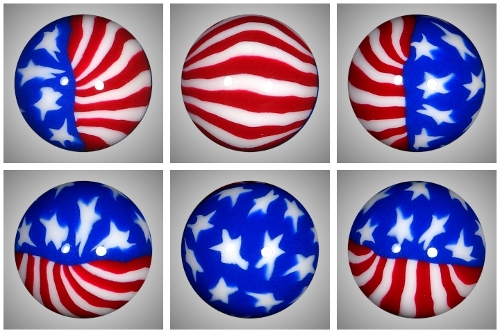

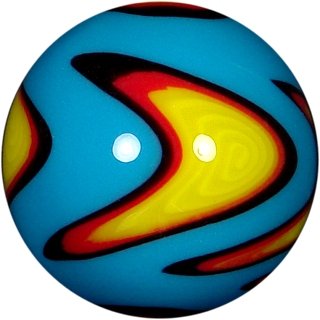

wonder what it would look like as a marble. One of my best sellers on eBay is a

vintage looking marble that I call a Christensen. Its patterned after the

marbles from two popular vintage marble manufacturers and has a lot of bright

electric colors, with swirls or flame patterns running throughout.

Q. How long does it take to make a marble?

A. That’s a tough question to answer. Once I figure out how to make a specific

pattern, it may only take 15 minutes to make one marble; however, it could take

days, even weeks, to figure out how to perfect the pattern. With vintage marble

replicas, it takes hours to come up with design and I have to reverse engineer

it in order to recreate it. Some of my marbles are formed from a cane which is a

long cylinder of clay. I can usually get 5 or 6 marbles from a cane. But, while

it may only take 5 minutes to make each marble once the cane is produced, it may

take an hour to make the cane. Every marble is different and I can never tell

how long it will take me to create any of them. Coming up with new marble

designs and making prototypes can be very time consuming.

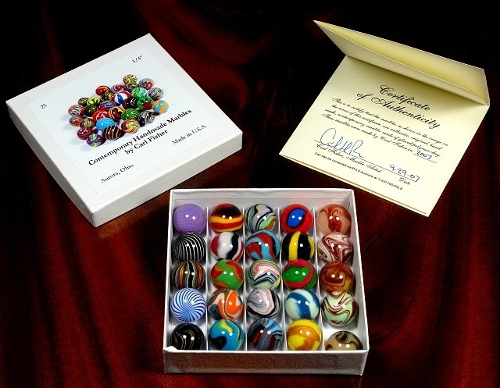

Q. How has the community responded to your polymer clay marbles?

A. So far, the response has been great. I sell my marbles at marble shows and I

sell them on eBay under my User ID, palsauctions. I sell about five lots a week

on eBay. I sold one 11/16 Golden Rebel for $56 which was the most a single

marble of mine ever sold for. The eBay feedback has been very positive also.

Some people have left feedback like, Awesome, Beautiful, Incredible, Fantastic

Talent, You're a Genius, and lots of other encouraging feedback. The best

feedback is when a customer buys again. Then I know they really like them. I

have a few repeat customers, and hope for more once the word gets out. I plan on

making marbles for a long time, so hopefully some of these early ones will go up

in value just like the first examples of any artists work. I offer a Certificate

of Authenticity with each marble I make which includes a photograph of the

marble, the size, the month and year it was made, and my signature. And eBay is

really nice because it affords me the opportunity to market them worldwide.

Q. How much time do you spend each week making marbles?

A. Not as much time as Id like. I usually make them on the weekends, if I have

nothing else scheduled. Ill work for a few hours at a sitting and make about 30

marbles.

Q. When you’re not making marbles, what do you do?

A. I work for IBM and just celebrated my 22nd year anniversary. I sell IBM

storage systems that support businesses in the areas of disaster recovery and

business continuance, and I work with some of the largest companies in the

world. Its a fascinating job and its very challenging. We use the latest

computer technologies to come up with innovative solutions to our customers

problems. I think some of that innovative thinking rolled over into my marble

making.

Q. I’ve heard your marbles called Green marbles. Whats that mean?

A. Anything environmentally friendly, or energy efficient, is called Green. An

example of green energy would be producing electricity from wind power. My

marbles are made from polymer clay. The clay hardens just by baking it in my

kitchen oven at a low temperature for a short time. Plus, I can bake dozens at a

time. Therefore, they don’t take much energy to produce. Melting glass, on the

other hand, requires very high temperatures for relatively long periods of time.

So, If you’re concerned about global warming, my green marbles are definitely

for you.

Q. Some people call you The Marbler. How did you get that name?

A. My wife and I have a favorite restaurant that we frequent every week. There

was an article in the Antique Week about my marbles a while ago, and one of the

owners of the restaurant recognized me from the photos in the article. They

called me the Marbler, and its stuck even since. The staff at the restaurant

often makes suggestions for new designs, and I take some of my newest ones each

time we go there. They enjoy looking at them, and some of the staff have helped

me name them. They were the ones that started calling me The Marbler, and now

others are calling me that. I like the name and am thinking of getting it as my

license plate.

Q. Where do you see your marble business headed in the future?

A. Based on current demand, there is a good market for them. Right now, I think

I am the only person in the world making marbles out of polymer clay at this

level. I have pioneered some new methods to make them look really glass-like.

Producing marbles from polymer clay that look like glass wasnt even thought

possible a few years ago. Now that people see it can be done, I am sure others

will want to try their hand at it. I plan on continuing to improve the quality

of my marbles and I have enough new design ideas to keep me busy for a very long

time.

Q. Are you planning on sharing your methods with others?

A. I show the process to everyone I can drag into my studio. I share most of

what I do, but there are a few trade secrets that I don’t want let out just yet.

I have kept extensive documentation and am planning on writing a book on how to

make polymer clay marbles using my methods.

Q. I see you entered your first contest, the Glass Addiction Boards 3rd

Annual Alphabet Contest and you tied for 13th place as well as tied for Best Use

of Color. Were you pleased with that?

A. I was ecstatic to have even been invited to participate, but to win something

was even better. I was really honored just to be mentioned along with all the

other well known and established marble artists that competed in the contest. I

do use a glass core to make a lot of my marbles, so it qualified as glass. This

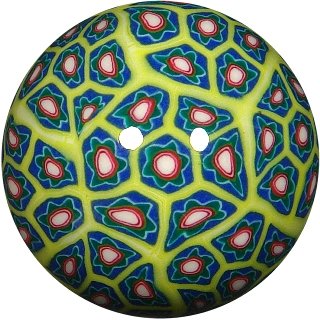

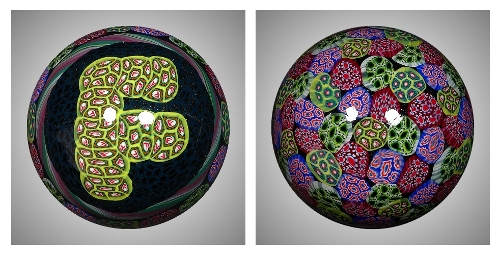

was my very first contest. I got to choose the letter F and worked on several

prototypes which took weeks of experimentation. It was, by far, the largest

marble I ever made at 2 3/8. I used a millefiori pattern which was made from

hundreds of tiny cells of colored clay. The millefiori cane was sliced and

placed on a glass core and then baked and glazed. When I found out I tied for

13th and tied for Best Use of Color, I couldn’t believe it. I was very happy

with the outcome and hope to be invited back again next year.

Q. Do you plan on exhibiting at the Buckeye Marble Collectors Show at the

Holiday Inn in

A. Unfortunately, I will be out of town on business, but I will definitely give

a few cases of my marbles to some of my marble dealer friends. Ill definitely be

at the Ohio winter show in New Philadelphia ,

Q. Have you ever thought of mass producing these?

A. I was recently commissioned to make 40 marbles for someone's 90th birthday

party. They were handed to each guest that attended the party, and they served

as a commemorative for the event. The guest of honor, the 90-year-old, played

marbles as a child, and she won awards for her marble shooting ability. The

marbles were a hit and everybody loved them. I would like to do some more volume

work like this for weddings, anniversaries and other important events. Marbles

make a great gift and can signify an important milestone in ones life.

Q. So, if someone wants to contact you, how do they do that?

A. My website address is carlfishermarbles.com or you can reach me at

951-694-6873. Or, just look on eBay or google

for Carl Fisher Marbles.

1. Has anyone ever purchased your

marbles assuming that they were glass and ended up being disappointed when they

realized they are polymer clay?

Not that I know of. All my marketing materials, eBay listings, and marble show

signs clearly state that they are made of clay. Most of vintage collectors that

have purchased my marbles use them as placeholders. If anything, I think they

are more amazed that they are made of clay. Most of my buyers are repeat

customers, too. Honesty is the best policy.

2. Like most glass artists, do

you have any plans to make other forms such as vessels or sculpture?

Maybe someday in the distant future. But, at this point, and for years to come,

I have enough ideas on paper that I still want to get into the simple spherical

form. I used to make kiln fired clay in the shape of a lit cigar. I hand painted

them and designed custom cigar bands. They looked just like the real thing too

and could easily get you kicked out of a restaurant.

3. Do you think that your

business will suffer if you publish a book on how to make polymer clay marbles?

Again, a book may be a long way off. And there are plenty of books on making

contemporary glass marbles which doesn't seem to hurt the top contemporary glass

artists. Everyone seems to have there own style. Regardless, even knowing how to

do something and actually doing it are two different things. I definitely do

intend on sharing my methods at some point. I am sure others will pick it up on

their own also, once they see that it is possible to make glass-looking marbles

from clay.

4. Have you ever considered

trying glass just for fun?

No. But, if anyone wants to invite me over call me!

5. Do you think that your methods

lend themselves better to vintage marbles than contemporary?

There is one quality of the clay that does limit the type of marbles that can be

made. But, its not a question of vintage versus contemporary. The clay itself

does not come in clear. So, I am limited to opaque-looking glass. There are some

translucent clays available, but most produce unpredictable or poor quality

results. Any real depth to the colors in my marbles is more attributable to

complex color mixing and the thick clear glaze that fools the eye. Fortunately,

some of the most desirable vintage marbles are rare brightly colored opaques in

specific recognizable patterns. My original intent was to make placeholders for

these in my own collection. I started making contemporary designs after the

6. What do you enjoy most when

you sell at marble shows?

The look on peoples faces when they see these marbles for the first time, and

the words that come out of their mouth like, Wow, These are clay?, and Now

that’s scary.

7. Which marble has been your

favorite to make?

Vintage Peltier NLRs are my favorite to collect, so I guess making marbles that

look like them are some of my favorites to make. I also like making one of my

own contemporary designs that has become quite popular. Its a red, white, and

blue stars and stripes design that looks like the American flag.