-

Posts

338 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by godown

-

-

What thats some great Advertising

-

That defendants do not produce in their flow-tank "streams" composed of clear and of different colored glasses; but defendants only produce bodies of clear and colored glasses, irregularly mixed and constituting gobs of the old style, or prior art gobs, in form or character; and defendants' marbles do not have the colored glass on the inside only, within the clear glass, but defendants' marbles have the colored glass on the outside and scattered all through the clear glass, irregularly.

-

Have you all read the judges findings ?

-

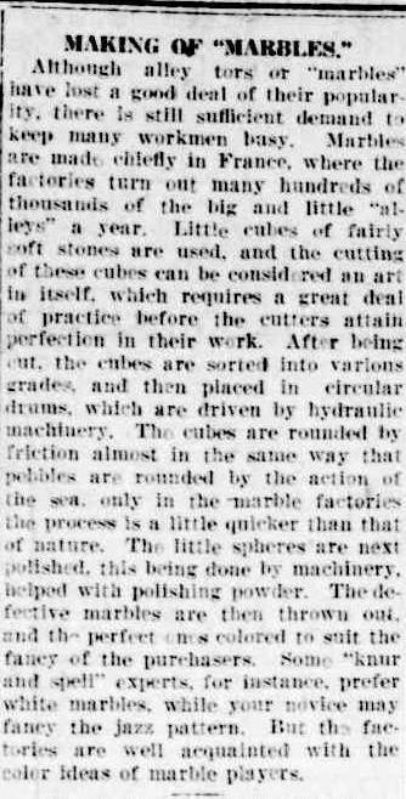

Here is an article that kind of backs up your theory Dan

-

Ive just had a little look around google books and come across this article

i think it pretty much spells out marble production in germany in the 20s at least traditional production anyway

Makes me wonder how long the transitional period lasted

-

Hi Bob

im guessing the bubbles probably started out round, the shape bubbles want to be and are elongated when the cane is stretched out and yep " frozen " as the glass cools

-

-

Cool thanks Ann

-

Yep thanks Galen did a search and yep your spot on asian patch thread in a made in Japan box mine`s a bit weak on the stripes Looks like they vary Knew id seen one somewhere

-

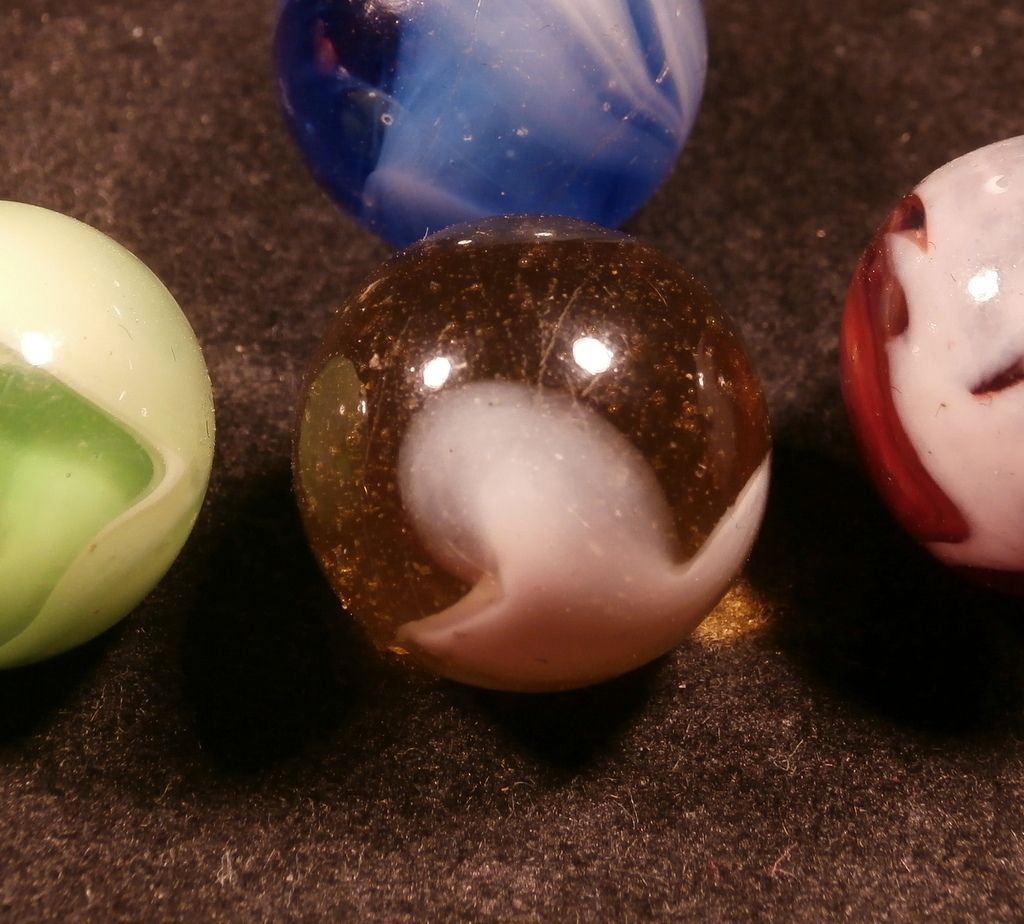

Im a bit lost with this one so any thoughts appreciated its spot on 21/32 Bit of an observation the glass may have been pretty cold and the marble hasn't smoothed out in the rollers as the heavier white is a little proud and in some spots i can catch it with the finger nail

and may explain a little the ruff as guts seam ?

Thanks

-

Thanks Cheese

-

Gave this one a run through the ID section a year or so back when i dug it with no real result i think due to my description and pictures

Since then and in particular over the last couple months ive been liking the striped transparent types and have managed to snag a few on ebay and with all the CAC action recently ive been comparing some of my Mibs with similar patterns

Well ive all but convinced myself this one is CAC What do you all think just a shade under 17mm or 21/32

White strip traveling around to other side of seam is also one part of S pattern

this pic looking down on the marble you can just make out the other cut / seam at 2.30 on the leading edge of white the next pic is the seam in the next picture

S

colour pic comparison

Probably got a bit carried away and to many pictures but its one of my favorites pay no attention to the biggest chip thats were i hit it with the shovel it came from under the floor boards of an old early 1900s home

Thanks

-

-

-

Another great picture Mibstified

-

Hi Winnie thank you i like these types also I believe there considered european striped transparents

-

-

Hey no problem Steph it was actually my intention to post the quote to the new thread but some how i muffed it

-

Although the principle is the same two opposing steel halfs the codds stopper marble mould was much different to the lead bullet mould it was circular and moulded 16 at a time

Below is a picture showing the moulds , and sprig belonging to John Ault and used for education

http://i169.photobucket.com/albums/u219/molly1photo/johns1.jpg

http://i169.photobucket.com/albums/u219/molly1photo/007.jpg

the lad to the left is holding what has come out of the mould i believe it is called a sprig the marbles were broken of and the ruff ends were if long manually filed off and then the marbles ground down in the machine below

http://img72.imageshack.us/img72/9718/fig30uv.jpg

Here is a small part of an article written by Mark Potten Credit to him for the pics and article

The plunger having been released, and the mould opened, the boy seizes the centre of the glass, now cooled to a semi-liquid, and runs off with it to the annealing oven, where he knocks the marbles off into a large iron box, to hold, say, 100 gross, sufficient for a day's work. They are there left to anneal thoroughly, and are then cooled gradually and taken to the grinding-room where they are carefully sorted, and those that have been broken off with pieces, too long for grinding are chipped first.

The best way to do this is with a file having a countersunk hole in it, into which the “get” or burr of the marble is placed, a small half-round file being used as a chopper. The marbles are then ready for grinding, which process is best accomplished by the use of Mr. Wickham’s grinding apparatus. This consists of a grindstone, working horizontally on a vertical shaft. The stone is placed and made fast to an iron table, and an iron bar is laid across the top, which keeps the surface smooth. Four boys can work at one grinding machine each being able to grind, with the use of the Wooden holders supplied by Mr.Wickham, about two gross an hour.

Water of course is used, and the waste is allowed to pass off through the curved pipe shown under the grindstone. When the burr is ground quite smooth and even with the rest of the marble the operation is completed. The counting is accomplished by an ingenious shovel with twelve grooves, each groove being made to hold a dozen marbles so that every time the shovel is used in counting one gross is scored They are then sent in boxes or casks to their destination. “

Hope this is of some interest and adds to the thread Presumably your marbles could have been made like this in large numbers

Craig C

-

-

-

-

-

[/url

[/url

Indian / Clambroth ??

in General Marble & Glass Chat

Posted

Hi Guys mate here in Oz was telling me he has a few dug marbles found during his bottle hunting

On the phone it sounded like an Indian but now having seen the pictures im wondering if its a Clambroth but it has that one fat stripe which makes me unsure

Any thoughts appreciated