-

Posts

691 -

Joined

-

Last visited

-

Days Won

1

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Shamrock Marbles

-

Even a blind squirrel can find an acorn once in a while. Stumbled across this early Chris' Robinson postcard. This must have preceded the branding of "Road and Tunnel Slag", as these marbles are called "Super Slags". Circa 1993/1994. Enjoy! John McCormick

-

Craig, Glass was purchased from Gabbert Cullet. So, whatever they bought as scrap and re-sold around 1993. The scrap had animal shapes. High probability it was Fenton. Gabbert sold tons of Fenton. I need to check mine under UV! John

-

Craig, I do have more information to share. Chris informed me that this was a very early "experimental" version of the R&T Slag. Not only was this a "developmental" marble, it was an "unusual" size (31/32"). Due to difficulties getting the machine to round, Chris cut the gather off the punty and into a "cup mold". The goal was to "pre-round" the gather as much as possible "before dropping on to the rollers". This was an early effort that he abandoned. "The cup mold was not completely finished and had circular machined marks." This makes sense, since you stated that your indentation is opposite the cut-mark. Hope this info helps. Now, I need to go look at my samples to see if there are any similar indentations! Sincerely, John McCormick "Shamrock Marbles"

-

Craig, Even more perplexed. I can't imagine what caused this. Sorry. Now, I can tell you that when we make larger marbles (1-1/4"+), we have to be very careful about when to remove from the marble machine. Even if the exterior seems cool and "set", the inner core can still be very hot. If you place a marble in the annealing kiln with a super hot core, that internal heat will migrate back to the surface. The surface can soften and the weight of the marble will create a flat spot (or an impression of the shelf material). Sometimes, a marble can slip through or jump out of the rollers. If it lands on something, it will make an impression. I just can't think of anything on Chris' machine that would make this mark. Again, sorry for not being much help. John P.S. I have always wanted to see Andy Davis make his marble/top stands. If you look at the bottom, they display a perfect "Road & Tunnel" pattern. A few years back, Alan sent me some beautiful examples.

-

Craig, No problem. Posts get buried quickly. As far as that indentation, I am puzzled. Could it have sat on something on the annealer? Maybe. Is that a concentric ring around the indentation? Does that area appear to be more "bubbly" than the rest of the surface? Sorry for more questions. John

-

Good morning, everyone! John

-

Shamrock says, "Howdy." Glad to see you post! John

-

Veiligglas Original Packaging

Shamrock Marbles replied to BuckEye 's topic in General Marble & Glass Chat

An additional thought... We know when the Closure was invented and when Veiligglas ended. One would suppose the dates were between 1957 and 1961. However, Craig noted the wording on the closure as "CARRY-SEAL II". Usually, when a patent approaches expiration, that invention is "modified" or "improved", so that product protection can be extended. Version 1 of the closure may have read "CARRY-SEAL" and Version 2 would be "CARRY-SEAL II". Maybe, the marbles were made before 1961 and stored in bulk boxes. They could have been packaged in smaller mesh bags much later (but before 1989) for Shackman to sell. Pure speculation on my part. Thanks, John -

Veiligglas Original Packaging

Shamrock Marbles replied to BuckEye 's topic in General Marble & Glass Chat

Okay, here is what I was able to find... The closure device is of German Patent origin from c.1957-1960. Inventor Hans Brenker (assigned to Neoplastik Braunschweig Kunststoffwerk) was awarded US Patent 2951273. https://www.google.com/patents/US2951273 It would be safe to say that Neoplastik made the closures and Hans was an employee. So, these packages could have been made and boxed from 1957 (creation of closure) to 1961 (end of Veiligglas). Very cool! John -

Veiligglas Original Packaging

Shamrock Marbles replied to BuckEye 's topic in General Marble & Glass Chat

Craig, What does the raised printing on the inside of the blue clip say? John -

Veiligglas Original Packaging

Shamrock Marbles replied to BuckEye 's topic in General Marble & Glass Chat

New Old Stock from a warehouse find and packaged for contemporary consumption? Shackman had a retail store in Manhattan. https://retail.shackman.com/ "For children over 3 years" is a voluntary label applied by toy manufacturers/retailers. "The Child Safety Protection Act", 1994, enacted specific labeling for marbles. So, pre-1994 for sure. Possibly 1980's? John -

At least there was a dial caliper in the background. The lack of photos showing all sides and how the fingers can obscure possible defects or roundness would bother me. The cut-line is interesting. John

-

Corky and his brother Patch

Shamrock Marbles replied to bumblebee's topic in General Marble & Glass Chat

Let's suppose... When getting the glass stream flowing, the spinning cup is retracted and the marble machine is pushed away. This glass piles up on the floor, to be later dug as cullet. Once the flow is consistent, the marble machine is rolled into place. Patch marbles are being produced, while the stream is adjusted to get the right size marble. Once all looks stable, the spinning cup device is engaged. Corks are now produced with the same colors as the patches before. If you look at the patent for the spinning cup, it is not overly robust. I also speculate that this device failed regularly and required it to be disengaged during a run. Corks stop and Patch production resumes. Corks would resume as soon as the device was fixed. My belief was that Cork production was the ultimate goal, but Patches are a natural by-product. Why toss a perfectly good marble? YMMV, John P.S. Both are awesome in their own way! -

Some appear to be taken under water. Surface bubbles on some marbles. John

-

Okay, how to classify these? Marbles from Linda Moore Simmons and Edna Eaton from various runs headed by Dave. These samples were made while at Mark Matthews' this past October 2017. Brett Young and Larry Zengel (Hot House Glass) did the gathering. Rounded in the Shamrock Mark II marble machine. Marbles range from 1.28" to 1.34" diameter. The one run I can identify as "Wonder Woman" 10/01/2013. For reference, the three small marbles are 0.59" diameter and the large marble is 1.32" diameter. Sincerely, John McCormick New info: Top Row of three: D.A.S. "True North" Marble Run, 09/29/2014. Bottom Row Left: "Wonder Woman", 10/01/2013. Bottom Row Middle and Right: "The Marble Buddies" Sistersville Marble Run at Sammy's Mountain Marbles, 09/25/2012. Thanks Linda!

-

Craig, You mentioned "one circular indentation opposite of the shear mark." Do you have a good photo of that? Greg, Do you have a link or can point me to Morphy's listing? (Thanks for your other post!) Thanks, John

-

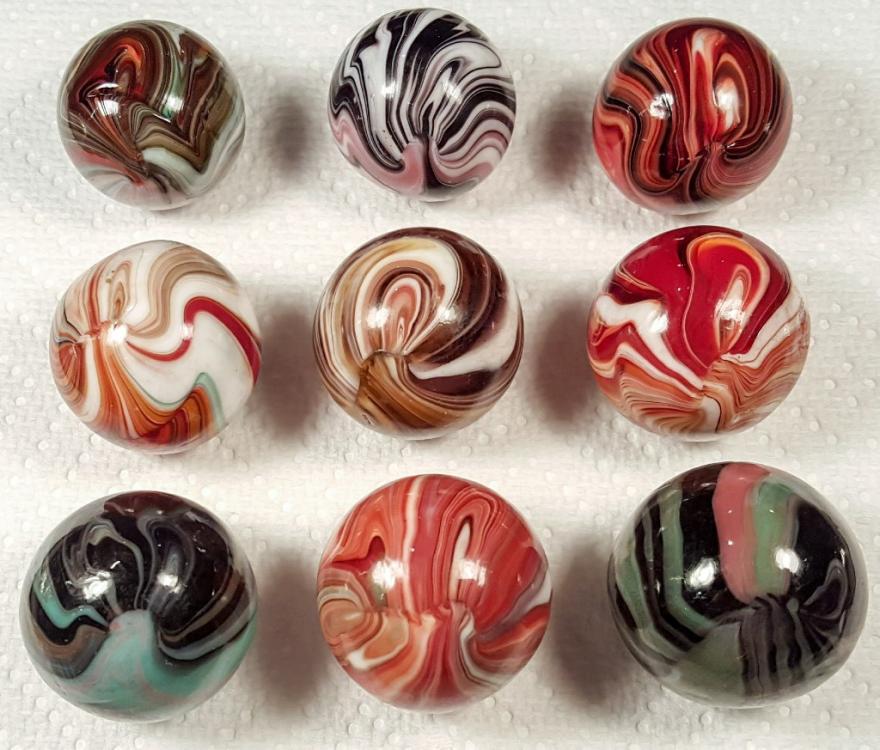

Craig, Here are nine of Chris' marbles. Smallest (upper left) is 35 grams and about 1.19" diameter. Largest (lower right) is 53 grams and about 1.38" diameter. Surfaces vary greatly from bumpy to smooth. John

-

Craig, Beautiful. The color combo, loops and striations are awesome. Would love to see the mable in hand and compare with my samples, but I would say yes. The cut line and glass wrapping are signatures of Chris' Road-and-Tunnel marbles. Please note: Others can produce the same effects. The colors are similar to those used by Chris'. The last batch of of white and purple marbles Chris' and I made had fractures. Does your marble have any cracks? Chris' machine had a series of different radius grooves that allowed him to make different diameter marbles. I will measure my samples and share those results. Happy Thanksgiving! John P.S. If Chris visits and comments, I will accept his opinion.

-

To All, Thanks for the generous compliments. Greg, Each marble has the distinctive DNA of the original artist and are signed by that artist. The miniature Matthews signature is a marvel unto itself. Those on Mark's website are from last year, 2016. Mark has some completely different marbles from this year's run, 2017. Mark dug way back into his archives. My favorites are his clam broth and peppermint reruns. Also, Hot House Glass has a grouping for sale. They sold their first listings (BIN) very quickly, but are going to do a second release soon. They anounce their Ebay listings via their FB account. Their construction and use of dichro make their marbles pop! Sincerely, John

-

You are most welcome. I presumed you were busy and didn't have time to research it yourself. After all, you did ask for help understanding why I used the adjective "rare". No raw or "rare" nerve here. It appears my usage of the word got you going first. However, I do like the way you try to twist who has the raw nerve. As far as being verbose, I do not apologize. I try to be clear. What I see on marble boards is the more an individual knows the shorter their post. This brevity, or economy, of words can come off as curt and uninviting for continued discussion. New (and old) people need slack and the chance to err. It is the job of experienced people to kindly spread any tribal knowledge. Again, it is all good here in Kansas. Sincerely, John

-

Mikie_T, For your viewing pleasure: https://www.youtube.com/watch?v=Z3mzj0-j2ww&t=6s Sincerely, John

-

Greg, Here are some large Shamrock slags (1-1/4" - 1-3/8" diameter) for reference. [Box set made by Craig aka "spara50"]. Totally different pattern than Chris'. Also, my cut lines are straight. Sincerely, John McCormick

.jpg.58275ff92f5a55247f9c2aa1d94a4b8f.jpg)

.jpg.d61a2c177f0ed2f2f5ead230517d64c2.jpg)

.jpg.fad05e95893f006472300bd3809eefc4.jpg)

.jpg.7128bf2de6970d2ecd6745de29c187d8.jpg)